Ǹjẹ́ o ti ṣe kàyéfì rí ohun tó ń jẹ́ kí ètò omi rẹ máa ṣiṣẹ́ láìsí ìjáde? Jẹ́ kí n sọ fún ọ nípa PPR Couplings. Àwọn ohun èlò tó wúlò wọ̀nyí dà bí gọ́ọ̀mù tó so gbogbo nǹkan pọ̀. Wọ́n so àwọn páìpù pọ̀ dáadáa, wọ́n sì ń rí i dájú pé omi ń ṣàn láìsí ìjáde omi kankan. Ó yani lẹ́nu bí irú kékeré bẹ́ẹ̀ ṣe lè ṣe ìyàtọ̀ ńlá nílé tàbí ibi iṣẹ́ rẹ.

Àwọn Ohun Tí A Yàn Pàtàkì

- Awọn asopọ PPR jẹ patakifún omi ìtútù. Wọ́n so àwọn páìpù pọ̀ mọ́ ara wọn dáadáa láti dá omi dúró kí ó sì jẹ́ kí omi máa ṣàn dáadáa.

- Àwọn ìsopọ̀pọ̀ wọ̀nyí lágbára, wọn kì í jẹ́ kí ó gbóná, wọ́n sì lè gba ooru. Èyí mú kí àwọn píìmù máa pẹ́ títí láìsí àtúnṣe tó yẹ.

- Yan PPR Soupling tó tọ́ ní ìbámu pẹ̀lú ìfúnpá àti lílo ẹ̀rọ rẹ. Máa ṣàyẹ̀wò nígbà gbogbo pé soup náà bá àwọn ohun tí o nílò fún pílọ́mù mu.

Kí ni PPR Sopọ̀?

Ẹ jẹ́ ká wádìí jinlẹ̀ nípa ohun tó mú kí PPR Coupling jẹ́ pàtàkì. Àwọn ohun èlò kéékèèké tó lágbára wọ̀nyí ni ìtìlẹ́yìn fún àwọn ètò omi òde òní. Wọ́n so àwọn páìpù pọ̀ láìsí ìṣòro, wọ́n sì ń rí i dájú pé omi ń ṣàn dáadáa láìsí ìjò. Ṣùgbọ́n kí ni wọ́n fi ṣe wọ́n, báwo ni wọ́n sì ṣe ń ṣiṣẹ́? Jẹ́ kí n ṣàlàyé rẹ̀ fún ọ.

Àwọn Ohun Èlò àti Àwọn Ohun Èlò PPR

A fi Polypropylene Random Copolymer (PPR) ṣe àwọn PPR Couplings, ohun èlò kan tí a mọ̀ fún agbára àti agbára rẹ̀ tó ga. Èyí kì í ṣe ike lásán—ó jẹ́ polima tó ń ṣiṣẹ́ dáadáa tí a ṣe láti bójú tó àwọn ohun tí àwọn ẹ̀rọ omi ń béèrè fún.

Èyí ni ohun tó mú kí àwọn PPR Couplings yàtọ̀:

- Agbára àti LíleÀwọn ohun èlò ìkún omi bíi okùn dígí àti talc ni a sábà máa ń fi kún un láti mú kí agbára àti ìfaradà pọ̀ sí i. Èyí mú kí wọ́n dára fún lílo agbára gíga.

- Agbara Kemikali: Àwọn PPR souplings máa ń tako àwọn ohun olómi, àwọn ásíìdì, àti àwọn kẹ́míkà mìíràn, èyí tó máa ń mú kí wọ́n má baà bàjẹ́ bí àkókò ti ń lọ.

- Iduroṣinṣin OoruÀwọn afikún pàtàkì mú kí agbára wọn láti kojú ooru gíga pọ̀ sí i, èyí sì mú kí wọ́n dára fún àwọn ètò omi gbígbóná àti omi tútù.

Ní gidi, àwọn àyẹ̀wò yàrá ti fihàn bí àwọn ohun èlò wọ̀nyí ṣe ṣeé gbẹ́kẹ̀lé tó:

| Irú Ìdánwò | Ète |

|---|---|

| Oṣuwọn Iṣan Yó (MFR) | Ó ń rí i dájú pé àwọn ohun èlò tó yẹ máa ń ṣàn dáadáa. |

| Atako Ipa | Ó ń fìdí ìdúróṣinṣin páìpù múlẹ̀ lábẹ́ agbára òjijì. |

| Idanwo Ipa Fọ́ | Jẹrisi pe awọn paipu le koju titẹ ti a sọ pato. |

| Agbára Hydrostatic Ìgbà Pípẹ́ | Ó sọ àsọtẹ́lẹ̀ iṣẹ́ ọdún 50. |

Àwọn ohun ìní wọ̀nyí mú kí PPR Couplings jẹ́ àṣàyàn tí a lè fọkàn tán nínú àwọn ètò omi ní gbogbo àgbáyé. Ṣé o mọ̀ pé ọjà PPR ní ilẹ̀ Yúróòpù jẹ́ $5.10 bilionu ní ọdún 2023? A retí pé yóò máa dàgbàsókè ní ìdúróṣinṣin, nítorí ìbéèrè fún àwọn ọ̀nà omi tí ó gbéṣẹ́. Jámánì, Faransé, àti UK ló ń ṣáájú, wọ́n sì ń rí i dájú pé àwọn ọjà wọ̀nyí ní àwọn ìlànà tó dára.

Báwo ni Àwọn PPR Conuplings ṣe ń ṣiṣẹ́ nínú Àwọn Ẹ̀rọ Plumbing

Ní báyìí, ẹ jẹ́ ká sọ̀rọ̀ nípa bí àwọn ìsopọ̀ wọ̀nyí ṣe ń ṣiṣẹ́ gan-an. Fojú inú wo bí o ṣe ń so àwọn páìpù méjì pọ̀. Ìsopọ̀ PPR ń ṣiṣẹ́ gẹ́gẹ́ bí afárá, ó ń ṣẹ̀dá ìsopọ̀ tó ní ààbò àti tí kò ní jìn. Àṣírí náà wà nínú àwòrán wọn àti àwọn ohun ìní wọn.

Èyí ni bí wọ́n ṣe ń ṣe àṣeyọrí èyí:

- Awọn ilọsiwaju Ohun elo: Àwọn ìsopọ̀ PPR jẹ́ èyí tó rọrùn síbẹ̀ ó lágbára, pẹ̀lú ooru tó dára àti agbára kẹ́míkà. Èyí mú kí wọ́n lè kojú àwọn wàhálà omi ojoojúmọ́.

- Àwọn Ọ̀nà Ìsopọ̀ Tí A Mú Dára JùÀwọn ìsopọ̀ òde òní máa ń lo àwọn ọ̀nà tuntun bíi titari-fit tàbí àwọn ọ̀nà tí a fi ń lo click-lock. Àwọn wọ̀nyí máa ń mú kí fífi sori ẹrọ rọrùn, wọ́n sì máa ń dín ewu jíjò kù.

- Àwọn Ẹ̀rọ Ọlọ́gbọ́n: Àwọn ètò kan tilẹ̀ ń so àwọn sensọ pọ̀ láti ṣe àkíyèsí ìṣàn omi, ìgbóná àti ìfúnpá ní àkókò gidi. Èyí ń ran lọ́wọ́ láti ṣàwárí jíjò ní ìbẹ̀rẹ̀ àti láti rí i dájú pé iṣẹ́ rẹ̀ dára jùlọ.

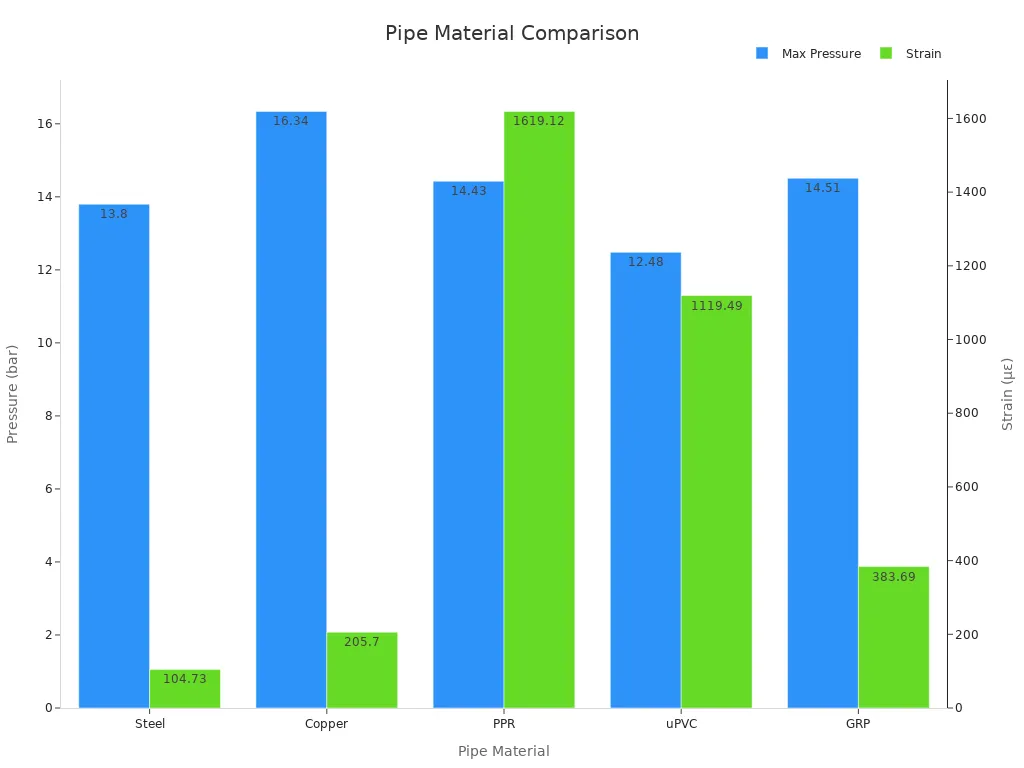

Láti fún ọ ní àwòrán tó ṣe kedere, àfiwé bí PPR ṣe ń ṣiṣẹ́ pẹ̀lú àwọn ohun èlò mìíràn nìyí:

| Ohun elo Paipu | Ìfúnpá Ìyípadà Tó Pọ̀ Jùlọ (ọ̀pá) | Ìwúwo (µε) | Ifiwera pẹlu Ọpa Irin |

|---|---|---|---|

| Irin | 13.80 | 104.73 | Ìtọ́kasí |

| Ejò | 16.34 | 205.7 | +15.65% titẹ, ìpele mẹ́ta |

| PPR | 14.43 | 1619.12 | -5% titẹ, 15x igara |

| uPVC | 12.48 | 1119.49 | -12.4% titẹ, ìpele 10x |

| GRP | 14.51 | 383.69 | +5% titẹ, ìfúnpọ̀ mẹ́ta |

Gẹ́gẹ́ bí o ti lè rí i, PPR Couplings ní ìwọ̀ntúnwọ̀nsì pípé láàárín agbára àti ìyípadà. Wọ́n dára ju ọ̀pọ̀lọpọ̀ àwọn ọ̀nà mìíràn lọ, pàápàá jùlọ nígbà tí ó bá kan mímú ìdàrúdàpọ̀ àti mímú kí ó pẹ́ títí. Ìdí nìyí tí wọ́n fi jẹ́ àṣàyàn tí a lè yàn fún àwọn ẹ̀rọ omi ilé àti ti ìṣòwò.

Àwọn àǹfààní ti PPR Conuplings

Agbara ati resistance si ibajẹ

Ní ti omi ìrọ̀gbọ̀, agbára rẹ̀ ló jẹ́ ohun gbogbo. Ṣé o fẹ́ ohun tó máa pẹ́, àbí bẹ́ẹ̀ kọ́? Ibẹ̀ ni àwọn PPR Couplings ti ń tàn. Àwọn asopọ̀ kéékèèké wọ̀nyí ni a ṣe láti kojú ìdánwò àkókò. Láìdàbí àwọn ohun èlò irin, wọn kì í jẹrà tàbí kí wọ́n bàjẹ́. Èyí mú kí wọ́n dára fún àwọn ètò omi, pàápàá jùlọ ní àwọn agbègbè tí omi líle tàbí omi tí a fi kẹ́míkà tọ́jú wà.

Mo ti rí bí àwọn ohun èlò ìbílẹ̀ bíi irin tàbí bàbà ṣe lè bàjẹ́ nígbà tí àkókò bá ń lọ. Wọ́n máa ń jò, àti pé pààrọ̀ wọn lè jẹ́ ìṣòro. Ṣùgbọ́n pẹ̀lú PPR Couplings, o kò ní láti ṣàníyàn nípa èyí. Ìdènà kẹ́míkà wọn máa ń mú kí wọ́n wà ní ipò tí ó yẹ, kódà nígbà tí wọ́n bá fara hàn sí àwọn ohun líle koko. Èyí túmọ̀ sí pé àtúnṣe díẹ̀ àti ìtọ́jú díẹ̀ ní àsìkò pípẹ́. Ó dà bí ẹni pé o ní ọ̀rẹ́ tí ó ṣeé gbẹ́kẹ̀lé tí kò já ọ kulẹ̀.

Ifarada otutu giga ati ore-aye

Ǹjẹ́ o ti ṣe kàyéfì rí bí àwọn ẹ̀rọ omi omi ṣe ń lo omi gbígbóná láìsí pé wọ́n ń bàjẹ́? Àwọn PPR Couplings ni a ṣe fún ìyẹn. Wọ́n lè máa ṣiṣẹ́ nígbà gbogbo ní ìwọ̀n otútù tó wà láàárín -20°C sí 95°C. Kódà ní àkókò òtútù tó ga tó 110°C, wọ́n ń pa ìdúróṣinṣin wọn mọ́. Ó yani lẹ́nu, àbí bẹ́ẹ̀ kọ́?

Èyí ni ohun tó mú wọn yàtọ̀:

- Ní 95°C, wọ́n lè kojú àwọn ìfúnpá tó tó 3.2 MPa láìsí ìfọ́.

- Lẹ́yìn ìgbà tí ooru bá ti gbóná tó 500 láàárín 20°C sí 95°C, wọn kò fi àmì àìṣeyọrí hàn.

Ipele iṣẹ ṣiṣe yii ko ni afiwe pẹlu awọn ohun elo bii PVC, eyiti o rọ ni iwọn otutu giga. Pẹlupẹlu, Awọn asopọ PPR jẹ ore-ayika. A ṣe wọn lati awọn ohun elo ti a le tunlo, eyiti o dinku ipa ayika wọn. Nitorinaa, nipa yiyan PPR, kii ṣe idoko-owo lori didara nikan—o tun n ṣe yiyan alawọ ewe.

Lilo igba pipẹ ni iye owo-ṣiṣe

Ẹ jẹ́ ká sọ̀rọ̀ nípa owó. Pípọ́ọ̀mù lè gbowólórí, ṣùgbọ́n PPR Couplings ní ojútùú tó gbéṣẹ́. Bó tilẹ̀ jẹ́ pé ìdókòwò àkọ́kọ́ lè dàbí èyí tó ga ju àwọn àṣàyàn mìíràn lọ, a kò lè sẹ́ pé a ó fi pamọ́ fún ìgbà pípẹ́. Ẹ ronú nípa rẹ̀—dínkù ìtọ́jú, dídínkù ìyípadà, àti iṣẹ́ tó dára jù. Ipò gbogbo ènìyàn ló jẹ́.

Àwọn ìwádìí fi hàn pé àwọn ètò PPR máa ń gba àwọn onílé àti àwọn ilé iṣẹ́ là ní àkókò púpọ̀. Àìlópin wọn túmọ̀ sí pé o kò ní ní láti ṣe àtúnṣe déédéé. Yàtọ̀ sí èyí, agbára wọn máa ń dín owó ìlò ilé kù. Ó dà bí ìgbà tí owó rẹ bá pọ̀ sí i. Tí o bá ronú nípa iye gbogbo rẹ̀, PPR Couplings jẹ́ àṣàyàn ọlọ́gbọ́n fún ẹnikẹ́ni tó bá fẹ́ fi owó pamọ́ ní àsìkò pípẹ́.

Bii o ṣe le Yan Asopọmọra PPR Ti o tọ

Yiyan asopọ PPR to tọÓ lè dà bí ohun tó ń ṣòro fún ọ, àmọ́ kò pọndandan kí ó rí bẹ́ẹ̀. Jẹ́ kí n ṣàlàyé àwọn kókó pàtàkì, àwọn ohun tí a sábà máa ń lò, àti àwọn àmọ̀ràn tó wúlò fún fífi sori ẹrọ àti ìtọ́jú. Nígbà tó bá yá, o máa ní ìgboyà láti ṣe àṣàyàn tó dára jùlọ fún àwọn ohun tí o nílò láti fi ṣe iṣẹ́ omi.

Àwọn Okùnfà Tí Ó Yẹ Kí A Gbéyẹ̀wò Fún Ìbáramu

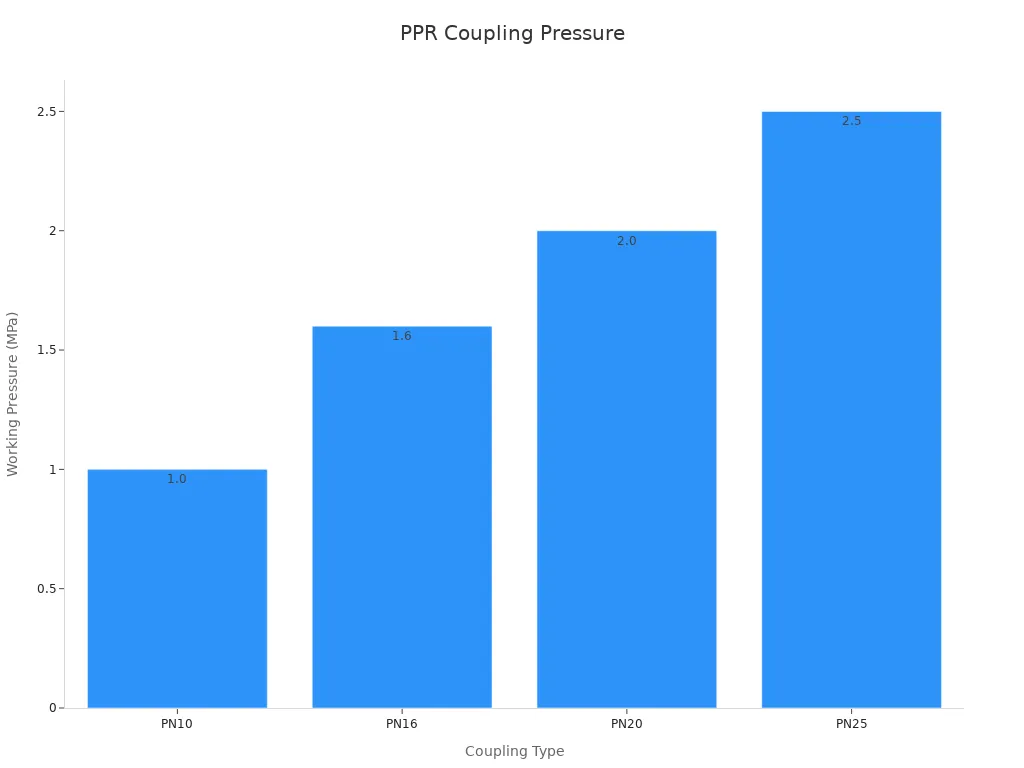

Nígbà tí o bá ń yan PPR Coupling, ìbáramu ni ohun gbogbo. O ní láti so ìsopọ̀ náà pọ̀ mọ́ titẹ, iwọn otutu, àti ìlò ẹ̀rọ rẹ. Èyí ni ìtọ́sọ́nà kíákíá láti ràn ọ́ lọ́wọ́ láti pinnu:

| Irú | Ifúnpá Iṣẹ́ (Mpa) | Àwọn ohun èlò ìlò | Ibiti Odi Sisanra |

|---|---|---|---|

| PN10 | 1.0 MPa | Awọn eto omi tutu, irigeson titẹ kekere | 2.0-3.5 mm |

| PN16 | 1.6 MPa | Àwọn ètò ìpèsè omi ilé onípele púpọ̀ | 2.3-4.2 mm |

| PN20 | 2.0 MPa | Igbona otutu giga, awọn ọpa ile-iṣẹ | 2.8-5.4 mm |

| PN25 | 2.5 MPa | Awọn eto nya titẹ giga, awọn ile-iṣẹ pataki | 3.5-6.5 mm |

Fún àpẹẹrẹ, tí o bá ń ṣiṣẹ́ lórí ẹ̀rọ omi tútù, PN10 ni ohun tí o fẹ́. Ṣùgbọ́n fún àwọn ẹ̀rọ steam onítẹ̀sí gíga, PN25 ni àṣàyàn tí ó dára jù. Máa ṣàyẹ̀wò àwọn ìlànà pàtó láti rí i dájú pé ó báramu dáadáa.

Awọn Ohun elo ti o wọpọ ni Awọn Plumbing Ibugbe ati Iṣowo

Àwọn PPR Couplings jẹ́ ohun tó wọ́pọ̀ gan-anMo ti rí wọn tí a lò nínú gbogbo nǹkan láti inú omi ilé tó rọrùn sí àwọn ètò ilé iṣẹ́ tó díjú. Àwọn ohun tí a sábà máa ń lò nìyí:

- Àwọn ètò ìpèsè omi ilé

- Ifijiṣẹ omi mimu (awọn eto omi gbona ati tutu)

- Awọn nẹtiwọki alapapo ilẹ didan

- Awọn ọna omi ile-iṣẹ fun awọn ile-iṣẹ kemikali ati ounjẹ

- Àwọn ètò ìrísí omi oko

Àìsí majele àti àìlègbéraga wọn ló mú kí wọ́n dára fún àwọn ètò omi mímu àti àwọn ohun èlò ìgbóná. Yálà o jẹ́ onílé tàbí agbáṣe, àwọn ohun èlò ìsopọ̀ wọ̀nyí jẹ́ àṣàyàn tó ṣeé gbẹ́kẹ̀lé.

Awọn imọran Fifi sori ẹrọ ati Itọju

Fífi PPR Couplings sí àti títọ́jú wọn rọrùn ju bí o ṣe lè rò lọ. Àwọn àmọ̀ràn díẹ̀ tí mo ti rí wúlò nìyí:

- Ilana Fifi sori ẹrọ: Lo ìsopọ̀ socket. Gé paipu náà, gbóná àwọn ìpẹ̀kun rẹ̀, kí o sì so wọ́n pọ̀ dáadáa.

- Ìfipamọ́ àti Ìtọ́jú: Pa iwọn otutu mọ laarin -20°C ati +40°C lakoko ipamọ. Daabo bo awọn asopọ kuro ninu itankalẹ UV ki o lo awọn fila lati dena idoti.

- Awọn iṣeduro Itọju: Ṣe àyẹ̀wò ètò náà déédéé. Máa fọ omi rẹ̀ nígbàkúgbà láti mú àwọn ìdọ̀tí kúrò. Dá àwọn ìjò omi dúró lẹ́sẹ̀kẹsẹ̀ kí o sì máa ṣe àkọsílẹ̀ gbogbo àtúnṣe.

Nípa títẹ̀lé àwọn ìgbésẹ̀ wọ̀nyí, o máa rí i dájú pé ètò omi rẹ dúró dáadáa àti láìsí ìṣòro fún ọ̀pọ̀ ọdún.

Àwọn PPR Couplings jẹ́ ohun tó ń yí ìyípadà padà nínú iṣẹ́ omi. Wọ́n pẹ́, wọ́n ń lo agbára, wọ́n sì jẹ́ ohun tó dára fún àyíká. Àwọn ìsopọ̀ wọ̀nyí máa ń dín ìpàdánù ooru kù, wọ́n máa ń dín agbára kù, wọ́n sì máa ń dín agbára kù. Bí wọ́n ṣe ń fi wé àwọn ohun èlò míì nìyí:

| Mẹ́tírìkì | Àwọn PPR Sopọ̀ | Àwọn Ohun Èlò Míràn (Irin/Kọnkírítì) |

|---|---|---|

| Ìgbékalẹ̀ Ooru | Kekere | Gíga |

| Lilo Agbara | Gíga | Díẹ̀díẹ̀ |

| Ipa Ayika | Rere | Oniyipada |

Pẹ̀lú ìgbà pípẹ́ tí wọ́n ń lò àti bí wọ́n ṣe ń náwó tó, wọ́n dára fún ilé àti iṣẹ́ ajé. Kí ló dé tí o kò fi ṣe àwárí PPR Couplings fún iṣẹ́ omi ìfọṣọ rẹ tó ń bọ̀? Ìwọ yóò gbádùn àwọn àbájáde náà!

Awọn ibeere ti a maa n beere nigbagbogbo

Kí ló mú kí àwọn PPR Couplings dára ju àwọn ohun èlò irin lọ?

Àwọn PPR Souplings kì í jẹrà tàbí kí wọ́n bàjẹ́. Wọ́n fẹ́ẹ́rẹ́fẹ́, wọ́n pẹ́, wọ́n sì jẹ́ ohun tó dára fún àyíká. Jù bẹ́ẹ̀ lọ, wọ́n rọrùn láti fi sori ẹrọ àti láti tọ́jú wọn ju àwọn ohun èlò irin lọ.

Ìmọ̀ràn:Yan PPR Couplings fun awọn eto omi pipẹ laisi wahala ibajẹ.

Ṣé àwọn PPR Couplings lè kojú àwọn igbóná tó le koko jù?

Dájúdájú! Wọ́n ń ṣiṣẹ́ dáadáa láàárín -20°C àti 95°C. Kódà àwọn òkè ooru tó wà fún ìgbà díẹ̀ tó jẹ́ 110°C kò ní ba wọ́n jẹ́. Wọ́n ṣe wọ́n fún àwọn ètò omi gbígbóná àti omi tútù.

Ǹjẹ́ àwọn PPR Couplings kò léwu fún omi mímu?

Bẹ́ẹ̀ni, wọn kì í ṣe majele, wọn kò sì ní àwọn kẹ́míkà tó lè pani lára. Wọ́n dára fún àwọn ètò omi tó lè mu omi, wọ́n sì ń rí i dájú pé omi tó mọ́ tónítóní àti tó ní ààbò wà níbẹ̀.

Àkíyèsí:Agbara kemikali wọn jẹ ki wọn pe fun lilo ibugbe ati iṣowo.

Àkókò ìfìwéránṣẹ́: May-13-2025